Reducing Flux Splatter in Sensors and Camera Modules

With the increased use of electronics in new technology areas flux formulations are being developed to address the new and existing requirements

For sensors and camera modules used for Advanced Driver Assistance System (ADAS) and internet of things (IoT) applications, there is a demand for no-clean flux formulations in lead-free solder paste, which can reduce flux splattering during reflow.

Development was done on a specially adopted flux chemistry, which helped to reduce solder/flux spattering without the use of a specially developed reflow profile adjustment in an air reflow atmosphere. The flux chemistry in the Sn3Ag0.5Cu solder paste was developed so that the flux residue layer can cover the molten solder surface during reflow preventing splattering.

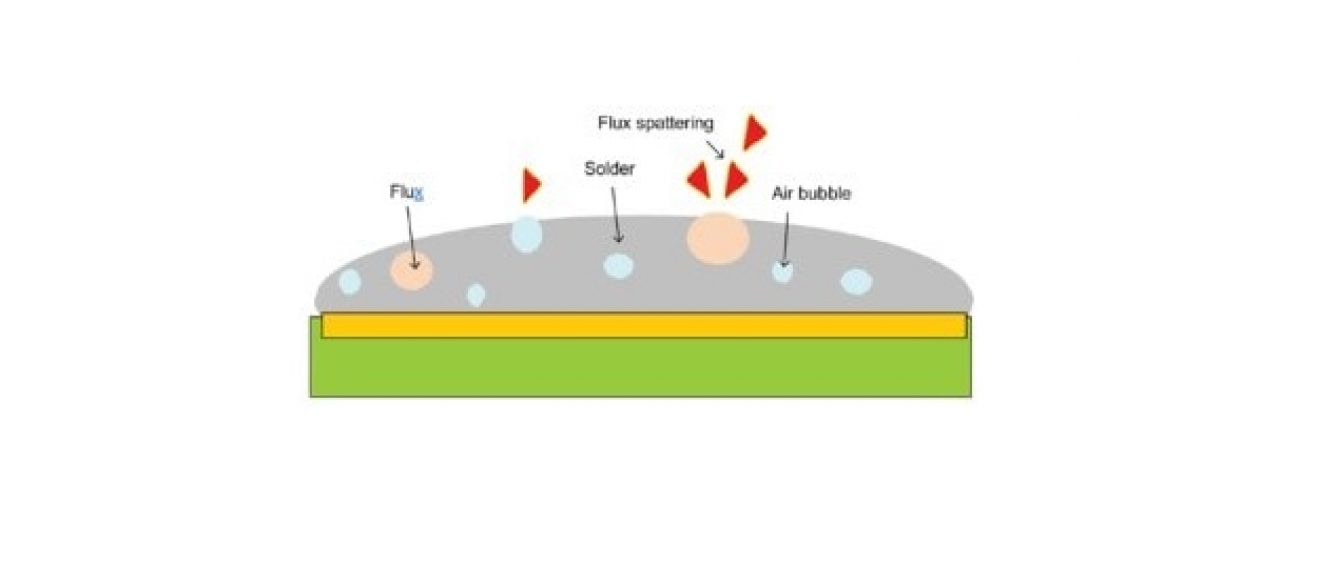

Tests were done on a copper plate printed with solder paste and a copper plate placed slightly above the re-flowing solder paste on the test vehicle to measure flux splattering with a variety of reflow profiles evaluated. While the conventional solder pastes required an increase of the preheat temperature to drive off volatile flux components to reduce splattering, this developed paste successfully prevented the occurrence of the splatter regardless of the type of preheat and reflow profile used. The results of the work will be reported in this article Introduction During surface mount assembly with solder paste, flux splattering may occur during reflow. Flux splattering occurs as flux components disperse when gas is generated, which happens when flux components contained in solder paste dissolve and volatilize and are expelled from the solder (Figure).

Flux spattering causes problems, such as the generation of a contact failure, which occurs when flux adheres to the contact point of connectors, as well as illuminance and recognition errors that happen when flux adheres to light-emitting diodes (LED s), lenses, and sensor components. As a means to prevent splattered flux from adhering to components, some customers use protective tapes to reduce such flux attachment. To lessen these defects and reduce the requirement for protective tapes in these growing applications, solder pastes that do not cause the occurrence of flux splattering are increasingly needed. This article reports on tests to determine flux splattering generation timing, conditions of the occurrence of splattering which are dependent on reflow profile, and measures to reduce flux splattering through the development of the flux in the solder paste.

Source : smt2020 oct2020 magazine