What’s the Deal with Flexible PCBs?

When people think of printed circuit boards, they often think of rigid boards with components mounted to them. But the term ‘PCB’ can actually refer to both rigid and flexible PCBs.

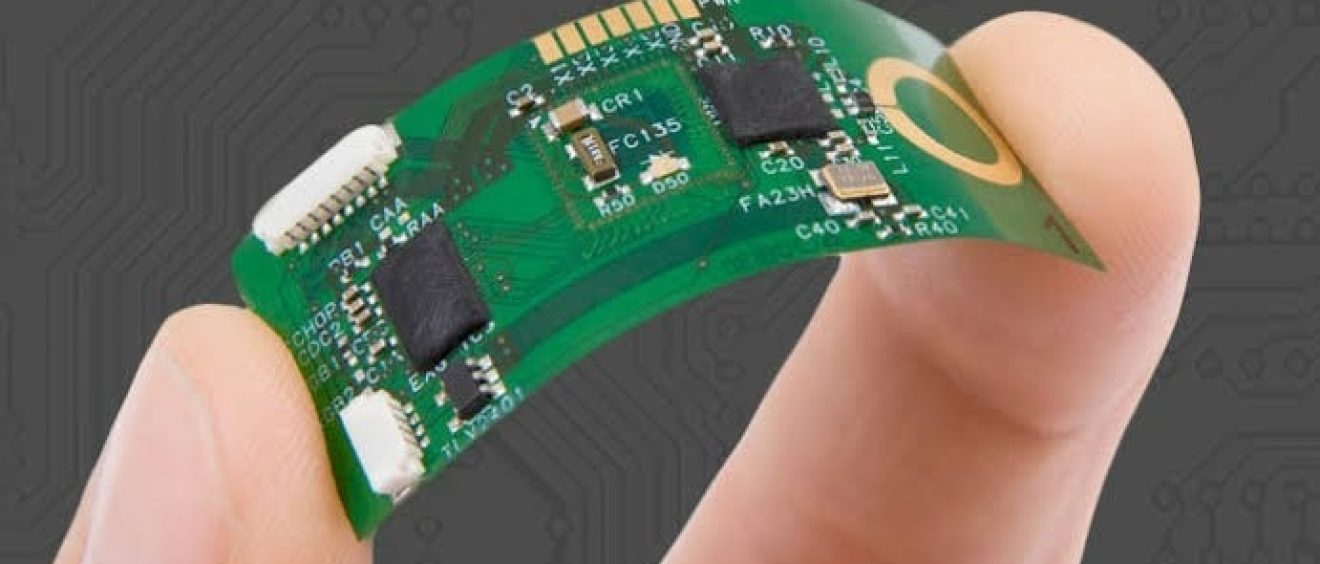

Flexible PCBs — or ‘flex circuits — are characterized by a malleable base material and derive their name from their ability to mould to the electronic device or product.

This technology has been used for interconnecting electronic devices in one form or another since the 1950s. However, flexible PCBs have recently gained immense popularity — unsurprising given that they can be shaped, bent and twisted into almost limitless configurations!

The ideal fit for a range of applications

Many of the most common electronics devices (TVs, laptops, computer monitors and children’s toys) use rigid PCBs. But what about flex circuits?

Flexible PCBs can also be found in a lot of everyday devices — from cameras and tablets to smartphones and wearable.

Basically, any ultra-compact, high-performance device. Even some under-the-counter LED lights use flex circuit technology because it makes installation easier.

Compared to an ordinary circuit board assembly, flexible PCB designs require only about 10 per cent of the space and weight, meaning greater flexibility when it comes to the final product. In most cases, flex circuits are made of polyimide or a polymer film, which dispel heat better than the types of materials typically seen in rigid circuit boards. This means flexible PCBs can withstand extreme temperatures. Resistance to high temperatures usually comes with excellent chemical, radiation and UV exposure resistance, too. A flexible printed circuit board also requires fewer interconnects, connectors, contact crimps and solder joins — meaning fewer potential sources for failure. This reliability makes them an excellent option for critical devices such as those found in the medical industry

So, why not use flex circuits all the time?

Flexible PCBs are undoubtedly useful, but they can’t replace rigid circuit boards for all applications. Manufacturing flex circuits requires a broad range of specialist process equipment — from laser direct imaging and flying probe testing to vacuum lamination presses and small drilling machines. That being said, flex circuits can eliminate the need for components such as connectors and wire harnesses — helping to reduce the cost of materials and the PCB assembly. However, more often than not, the ideal solution for an innovative electronics product is one that integrates flexible circuitry with rigid circuit boards. Some manufacturers are now even starting to use hybrid rigid-flex PCBs, which involve connecting rigid circuit boards using ribbon-like flexible circuits. These boards combine the strengths of both rigid and flexible PCBs to meet various engineering needs and are frequently used in laptop computers and medical devices.

Source: emsolutions