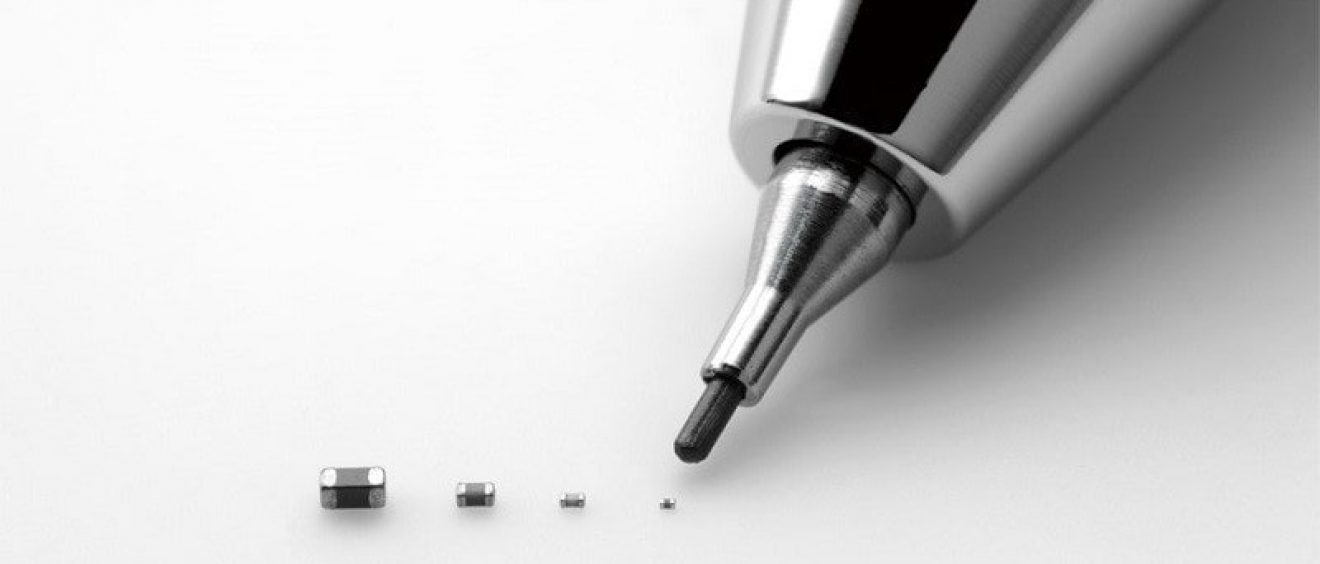

PCB Rework of 0201 Packages

As electronic passive components continue to shrink in size, methods for their rework need to be developed by electronic manufacturers to maintain and support PCB assembly processes.

Here, compare and outline of a few of these rework methods. 0201 package type is one of conventional methods that has been used many times but tombstone defects that are so common for this type, are commonly caused by the pads heating up at different rates. A thermal mass imbalance may cause one of the pads to heat at a different rate compared to the other. In addition, the very small pad geometries of the 0201 packages make solder paste printing consistency a challenge, which can also cause defects.

The most common technique used to remove and replace 0201 body style components is through the use of a conductive hand soldering system.

The tips themselves are fragile structures and are easily damaged, which means care needs to be taken by the soldering technician. While hand soldering is the fastest method for the removal and replacement of the 0201, it requires a high degree of operator skill and dexterity.

Hot Air Rework is another reflow method employed by soldering technicians for the rework of these small passive devices is by using a hot air source.

A split vision rework system, which assists the operator in aligning the part to the pads, reduces the degree of skill required to rework these small packages When using a hot air rework system, the removal of the component is accomplished by using a hot air nozzle specifically designed to push out low airflow. For replacement of the 0201 component, a high-resolution camera, means device placement can be more precise and repeatable vis-à-vis the hand soldering approach. This type of soldering is ideal for these components.

source : PCB Rework of 0201 Packages By Bob Wettermann, BEST INC