Electronics Supply Chains Splitting Between China and U.S

Protection of the global supply chain is important for high-tech companies

Chinese companies need to avoid U.S. criticism and potential U.S. penalties, trade restrictions related to possible export control violations. As demonstrated, China will try to build their own industry by themselves. Over the past two decades, China welcomed multinational companies. But now in the coming years and decades, China will say no, it must be produced by Chinese. China makes about half of the world’s electric vehicles, and it will very likely continue to play a key role in the future. Six of the top-ten battery makers for electric cars are in China.

according to the assertion of tech companies, the U.S. can slow China down, but that’s futile in the long run unless the U.S. undergoes a major reboot in supply chains in China.. Beside transparent area of automobiles and laptop for domestic and multinational companies Chinese companies have wide range of electronic materials supply chain like Flat-panel displays (FPDs) that China will relinquish its hold on FPDs, which are used ranging from U.S military to air traffic control monitors.

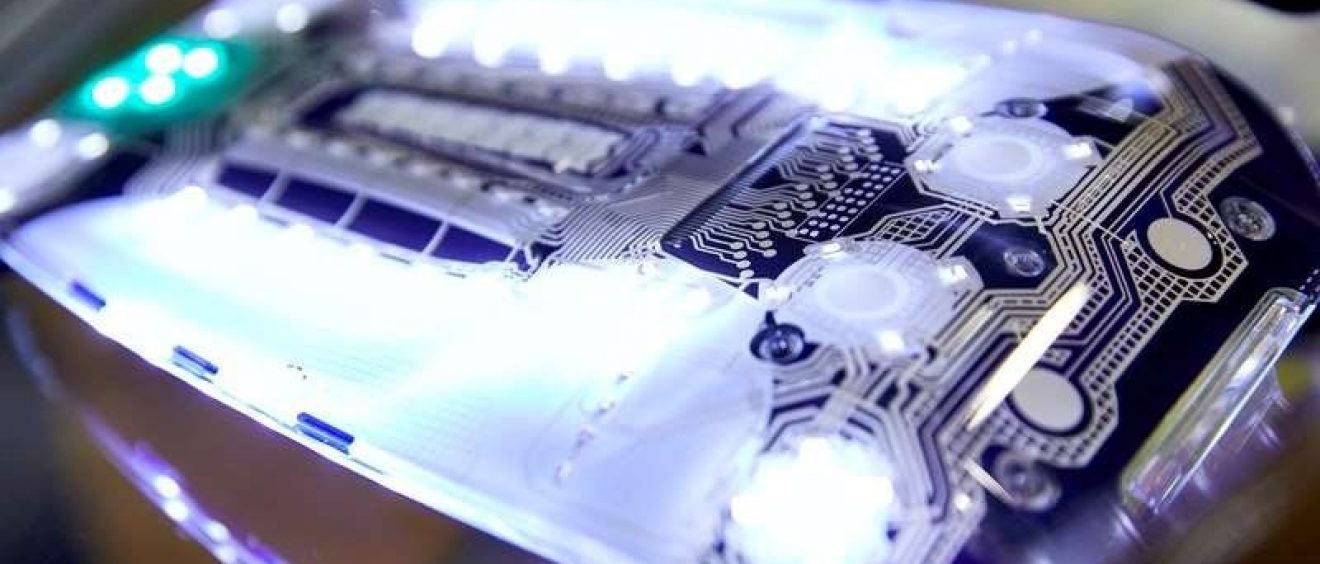

Another Chinese innovative alternative that are deployed across the automotive, consumer goods and medical device sectors of America is electrical circuits that is being added onto 3D surfaces and integrated within objects using a range of new techniques.

in-mold electronics and 3D printed electronics enable complete circuits to be integrated within an object. Between them the various approaches offer multiple benefits and innovation opportunities that include simplified manufacturing, reduced weight and novel form factors. With 3D electronics, adding electronic functionality no longer requires incorporating a rigid, planar PCB into an object then wiring up the relevant switches, sensors, power sources and other external components.

Another introduced approaches is laser direct structuring (LDS) that is the best-established approach to adding electrical functionality onto the surface of 3D objects. However, despite its widespread adoption, LDS has some weaknesses that One technology that is used for its weakness is the usage of dielectric materials that cause components to be mounted onto the surface.

Article Electronics Supply Chains Splitting Between China and U.S. By Alan Patterson EE Times